Potato Peeling Cutting Machine

The equipment is simple and generous in appearance, compact in design and small in floor area, which is very suitable for small processing plants and restaurants.

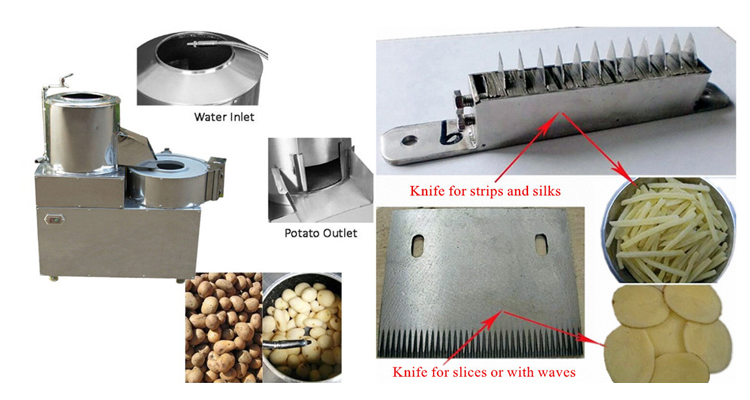

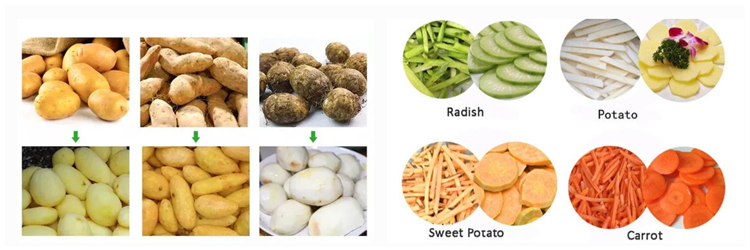

It can be peeled or cut separately, which is more functional and practical; The use of emery peeling, only the skin of potatoes to avoid waste of raw materials.

Slicing, cutting and cutting can be done, and one machine can be used for many purposes.

Made of stainless steel, durable, rust-free and non-polluting ingredients, meeting the national food grade requirements.

Potato Peeling Cutting Machine Structure and Working Principle

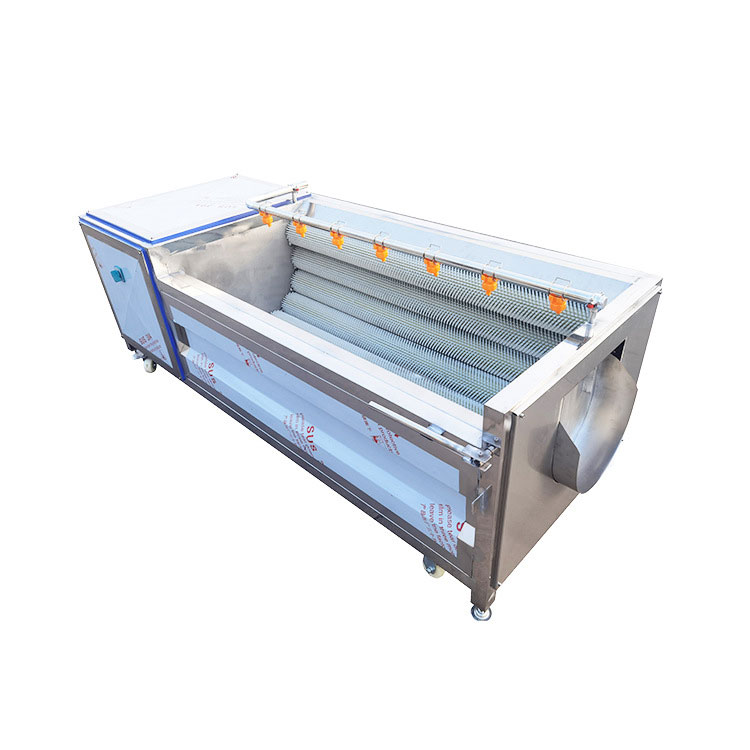

Put the potatoes or other vegetables into the grinding drum while turning on the tap. The rotating grinder will keep turning the potatoes, and by contacting with the diamond, the potatoes will rub against each other to achieve peeling. The skins are rinsed off by the water and flow out from the outlet.

By opening the gate of the outlet, the peeled potatoes will flow into the cutting drum. The final product will come off through the discharge gate of the cutting section. The waste material will be discharged through another outlet of the potato peeler and slicer.

Potato peeling and slicing machine is made of stainless steel, sanitary and durable.

The thickness of the finished product cut out by the fruit and vegetable cutting machine is adjustable from 1-10mm.

Slicing, shredding, cutting strips of good shape, smooth surface.

Potato peeling cutting machine adopts the principle of diamond grinding, high peeling rate, small loss.

English

English Spanish

Spanish