Potato Chip Production Line

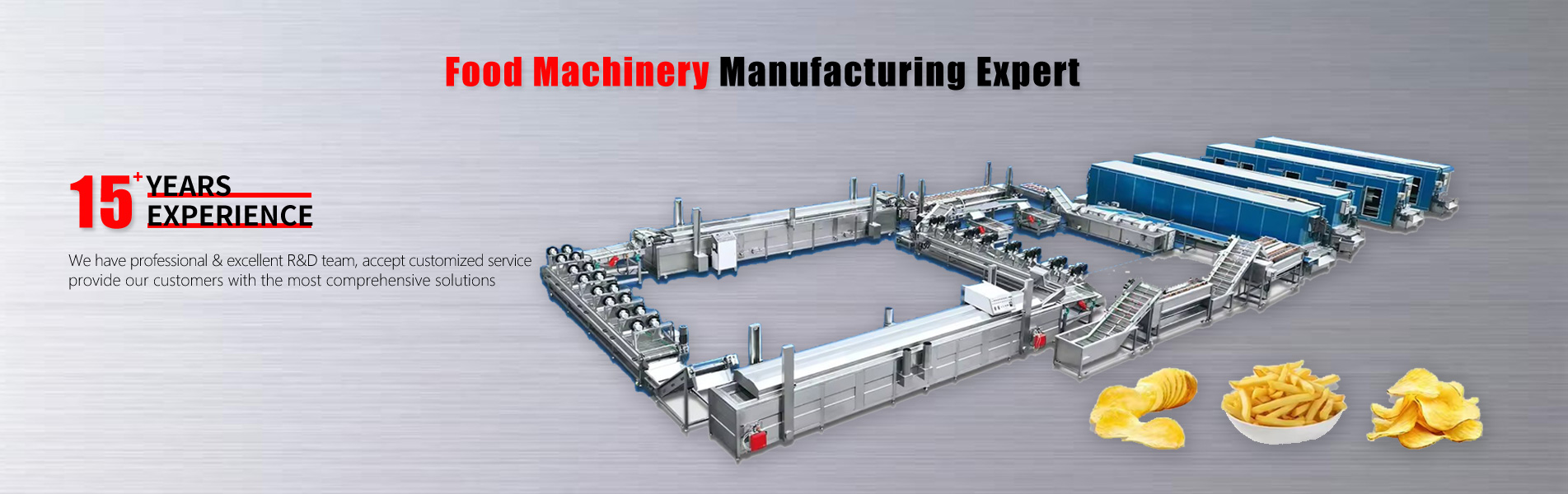

Potato Chip Machine Production Line Overview

Our potato chip machine production line utilizes advanced automation technology, specifically designed for the food processing industry, to provide efficient, energy-saving, and stable production solutions. The line covers every step of the potato chip production process—from washing, peeling, and slicing to frying, seasoning, cooling, and packaging. Our equipment ensures that the produced chips have an even texture, a crisp crunch, and a non-greasy taste, all while adhering to strict food safety standards.

Typical Potato Chip Machine Production Line Process

1. Raw Material Sorting

Manual or mechanical sorting is used to eliminate substandard potatoes, ensuring that only high-quality potatoes are used in production

2. Washing and Peeling

After entering the production line, potatoes are first cleaned with swirling water to remove dirt and impurities, and then a rolling or steam-based

peeling mechanism is used to remove the skin from the potatoes.

3. Slicing

Potatoes are sliced into thin, uniform pieces with adjustable thickness (typically between 1.2–2 mm), ensuring consistent texture and quality.

4. Blanching

The sliced potatoes are briefly treated with hot water to prevent oxidation, color changes, and to remove excess starch, improving chip quality.

5. Frying

Potato slices are fried at temperatures ranging from 160°C to 180°C until they turn golden and crispy.

6. Cooling and Deoiling

Excess oil is removed from the chips using powerful fans and then the chips are cooled to room temperature on a conveyor to prevent heat from

affecting the packaging process.

7. Seasoning

Fried potato chips are mixed with seasoning powders (such as salt, pepper, chili powder, cheese powder, etc.) to ensure

an even coating and enhance flavor.

8. Weighing Packaging

Automated packaging machines handle precise portioning and packaging. Options for vacuum packing or nitrogen-flushed packaging are

available to extend shelf life and maintain freshness

English

English Spanish

Spanish